How do you create a special design for a botanical greenhouse with a record amount of glass while keeping structural steel to a minimum? And still deliver stable tropical and desert climates in a North-European country?

Case Study Flora Köln

Public tender project

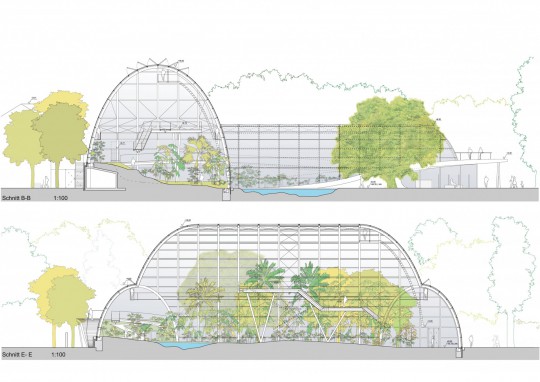

The new tropical glasshouse for the Flora Botanical Garden shows how advanced engineering and sustainable design can go hand in hand. Commissioned through a public tender, this project challenged our team to combine minimal steel, maximum glass and long-term climate durability in one elegant structure.

The Client’s Challenge

Historic Botanical heritage

Flora Botanical Garden is one of Germany’s premier botanical collections, renowned for both its historic heritage and its conservation mission. In 2021, the garden’s curators sought a new facility to:

- Simulate two distinct climates (tropical rainforest and arid desert) with precise humidity and temperature controls.

- Maximise natural daylight to support photosynthesis for 6,000 ageing, endangered specimens.

- Ensure long-term corrosion resistance in a high-humidity environment.

- Maintain visitor comfort and accessibility, including an adjoining orangery and canopy link to existing glasshouses.

Key constraints included a minimal steel profile for reduced shading and an uncompromising specification for durability over decades.

Innovative Design & Engineering

Elliptical Steel Framework

Architect Ilse Königs’ vision hinged on an elliptical truss system directly beneath the glass surface. By hot-dip galvanising the entire steel frame to a specified minimum zinc thickness, we delivered:

- Exceptional corrosion protection, far surpassing painted systems.

- Structural precision, with zero tolerance for deviation to prevent glass breakage.

- Aesthetic harmony, as the silver-grey galvanised finish complements the aluminium curtain walls.

High-Performance Insulated Glass

Light transmission and thermal performance

To optimise light transmission and thermal performance, we specified:

- Low-iron “clear” glass (reducing the characteristic green tint) with UV transmittance up to 70%.

- Trosifol Natural-UV PVB foil, boosting UV-transmittance in laminated roof panes to approximately 50% (versus <1% with standard PVB).

- Heat-strengthened and toughened panes, allowing thinner sections (lower weight) while resisting hail, windloads and accidental shocks.

- Silk-screen printed bird-protection glass in the orangery, using a lead-free ceramic “s1deONE” colour for long-lasting durability.

- Ködispace 4SG warm-edge spacers, ensuring optimal Psi and Ug values, permanent elasticity, moisture barrier integrity and high temperature resistance.

“Technically, this was a very advanced design, but the good cooperation and in-depth knowledge of Smiemans made it a pleasure to work together again.”

Dipl.-Ing. Ilse Königs, Königs Architekten PartGmbB

Overcoming Technical Bumps

Tight Tolerances

Mounting glass directly onto the galvanised steel demanded millimetre-perfect alignment. Any deviation risked pane failure during installation or in-service movement. Our quality control process included:

- In-factory 3D laser scanning of each truss.

- Pre-assembly mock-ups to verify fit.

- On-site jigging and laser verification before galvanisation.

Climate Computer Delays

Original commissioning targeted June 2022. However, supply chain disruptions postponed delivery of the specialised climate control units. We maintained client communication with regular progress updates, secured interim weather-protection measures for planting, and rescheduled works—ultimately planting the first specimens in mid-2023.

Maintenance Accessibility

Tropical plants and high humidity accelerate algae growth and condensation. Early in design, we integrated:

- Discreet access hatches in roof gutters.

- Removable floor panels over service trenches.

- Fixed walkways in canopy voids for annual engine and bearing inspections.

These ensure safe, efficient maintenance without harming the plant canopy or structural coatings.

Results & Impact

Knowledge Based building

- Environmental Performance: The greenhouse maintains stable tropical (≥ 80% RH, 28–30 °C) and desert (≤ 20% RH, 35 °C) zones with minimal energy use, thanks to solar gain and high-efficiency glazing.

- Visitor Engagement: The seamless glass shell and adjoining orangery canopy create an inviting path through climates, boosting footfall by 25 % during the first full season (2024).

- Conservation Success: 6,000 rare plants, including 200 species classified as “critically endangered” now thrive under optimal conditions, supporting vital research and restoration programmes.

- Industry Recognition: Awarded the BTTV Benelux Trophy for Thermal Galvanisation 2021 for “an outstanding technical and aesthetic achievement in galvanised steel”.

Lessons Learned

& Best Practices

- Integrate Finishing Processes Early: Hot-dip galvanising can alter steel geometry; planning around these tolerances is crucial.

- Prioritise Access for Maintenance: In high-humidity glasshouses, interior access routes preserve structural finishes and plant health.

- Choose Performance Glazing: Low-iron glass and UV-transmissive laminates drive plant growth and energy savings.

- Maintain Client Communication: Transparent updates during supply delays safeguard trust and project momentum.

Tropical greenhouse design for your location!

Curious how we can make this happen for you?

Projects like this show what’s possible when vision and knowledge meet.

If you’re planning a botanical or public glasshouse, let’s discuss how we can realise your ideas.

From design advice to complete realisation.